제품정보

Ceramic Band Heater

- 세라믹 밴드 히터는 최고 1600°F(870°C)까지 공급할 수 있는 중-고온 히터입니다.

제품 사양

제품 상세 설명

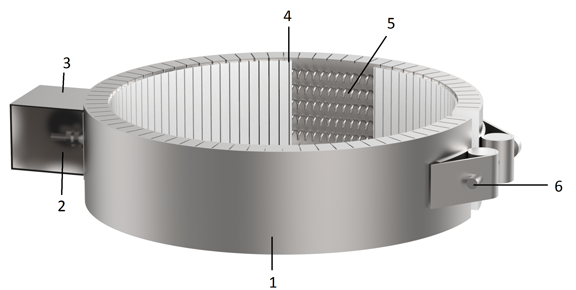

Ceramic band heaters are medium-to-high temperature heaters that have 648°C as a maximum working temperature. These durable heaters can have optional in-built ceramic fiber jackets that make them energy efficient. Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs. In a ceramic band heater, a nickel-chrome wire is embedded in a flexible outer wall made of special, interlocking ceramic tiles (KNUCKLES), which are assembled like a brick wall.

A ceramic fiber insulating mat and a stainless Steel/Aluminised Steel jacket cover this assembly. This construction prevents heat loss and reduces electrical consumption by 20%. Ceramic band heaters can be manufactured with different clamping mechanisms, terminations styles, holes, and cut-outs, perforations. The element winding is designed to heat the ceramic blocks to the point at which they radiate energy into the barrel as well as to conduct energy by being in contact with the barrel - fit is not as critical as in other types of bands.

Advantages of Ceramic Band Heaters

- Lower Operating Cost

- Longer Heater Life

- Higher Operating Temperatures

- Flexible

- Sheath Material

Steel or Stainless Steel

- Insulation Material

Ceramic Fiber Blanket

- Watt Density

Up to 45 W/in2

- Watt Ratings

500 - 5000 W

- Voltage

120-600 V

- Width

1 ½ - 6"

Construction

1. Stainless steel sheath: Generally we use aluminium coated sheath for oxidation resistance in a wide variety of environment but can also provide SS 304 stainless steel as per application requirements.

2.Screw Terminals: Screw terminals for maximum amperage carrying capacity and a firm connection with the winding.

3.Terminal Box: To provide protection against exposed terminals and helps guard terminals from spill over’s, dripping. Various terminal type use such as crimp on lead ceramic connector type with using of copper lug crimping and SS bolded terminal.

4. Resistance wire: Nickel Chromium 80/20 resistance wire for maximum heater life evenly wound for even heat distribution.

5.Ceramic fiber insulation: Ceramic fibres are used as insulation materials, because of their ability to withstand high temperatures.

6.Ceramic knuckles: High purity aluminium oxide ceramic knuckles selected for heating element winding process and maximum dielectric strength and thermal conductivity highly compacted for maximum heat transfer.

| Special Construction | |

Two-Piece Construction

| Terminal Box Construction

|

Maximum Allowable Watt Density in Watt/Sq. Inch

| Cylindrical Temperature (°C) | 1.5-3” ID | 3-10” ID | 20" ID |

94 | 52 | 47 | 41 |

150 | 51 | 46 | 40 |

205 | 50 | 45 | 39 |

260 | 46 | 42 | 36 |

315 | 41 | 38 | 31 |

370 | 37 | 33 | 27 |

425 | 29 | 25 | 20 |